Dark and bright places in apparel Sustainability

Welcome to "nouveau monde", a four-handed newsletter to better understand how to make the world better through the lens of retail. This is #66.

Thanks for you loyalty to Nouveau Monde if you’re returning reader! If you’re just new here, just subscribe for free to receive new posts and therefore support our work. It’s right at the end of this email

The menu du jour is about apparel.

Today's newsletter is 1.220 words, a 6-minutes read.

In the Dark Places

by Anthony

Breaking and sad news I just read : Patagonia, the sustainable brand, the one that its founder just gave all its belongings to Earth uses the same factories as fast-fashion brands!

We’ve talked many times about Patagonia in Nouveau Monde (recently here) because it is considered as a reference in the sustainable fashion ecosystem and it has an alternate speech.

So, what do we learn in this article and what are the answers of Patagonia?

First, despite its sustainable allegations and its supplier code of conduct, Patagonia uses the exact same factories as fast-fashion brands like Primark or Zara.

Therefore, conditions are the same for workers that make a Primark shirt one day and a Patagonia one the other. During their inverstigation in a giant factory, Follow the Money discovered that workers there worked about 70 hours a week. “It’s busy” says a manager to justify that. But Patagonia says in its code of conduct that workers shouldn’t work more than 48 hours a week, 60 in some specific cases when you have to pay overtime, and not for a long period of time:

Never bought any Patagonia garments but I must admit I’m a bit confused by these practices and a bit more by Patagonia’s answers in this article, which is basically:

Yes, we use the same factories, yes we have the same workers, the same wages, way lower than a living wage but we do that to change the system from inside as we have high standards and gold for the years to come.

Maybe, I don’t know and we shall follow this closely to to see Patagonia’s authenticity on that matter.

The article also talks about a recent move of the European headquarters from Annecy in the French Alps to Amsterdam and that the operation as been made the exact way a company that would like to optimize its taxes would have done. But Patagonia replies that it has never used the tax efficiencies of a cooperative. I really want to trust them but I must admit that the confidence is a little broken so far.

This reminds me several conversations I had recently with friends trying to do something to change our world : should we leave everything, pave our own way, refuse our consumer world led by GDP or should we transform the system by the inside and work for big companies and try and move them?

I don’t have the answer, but am a bit sad this morning.

Do you know Circ?

by Phil

I’m receiving a bunch of emails about some Demo Day and all the content proposed by all the incubators and accelerators I’ve been to, mostly in the US. It’s a very dynamic ecosystem. I can see the sustainable topic growing and that’s great news. I like to highlight startups in this domain, and that’s what Im going to do again this time.

The Extreme Tech Challenge (XTC) is another startup competition and ecosystem for showcasing the most innovative tech founders addressing what the United Nations call Sustainable Development Goals (SDGs). Also known as the Global Goals, were adopted by the United Nations in 2015 as a universal call to action to end poverty, protect the planet, and ensure that by 2030 all people enjoy peace and prosperity. Founded by two Silicon Valley venture capitalists, Young Sohn and Bill Tai, their mission is to empower entrepreneurs building innovative technologies that improve the world. The goal is to identify potential market-leading companies that can impact the world in a big way and provide the rocket fuel to help them scale faster. We partner with a number of leading tech conference on their programming (i.e. CES, TechCrunch, Vivatech, Slush, Harman Tech Forum) as well as their own standalone events and dinners (i.e. Neckerverse on Richard Branson's Necker Island). Check out highlights (video) from 2022.

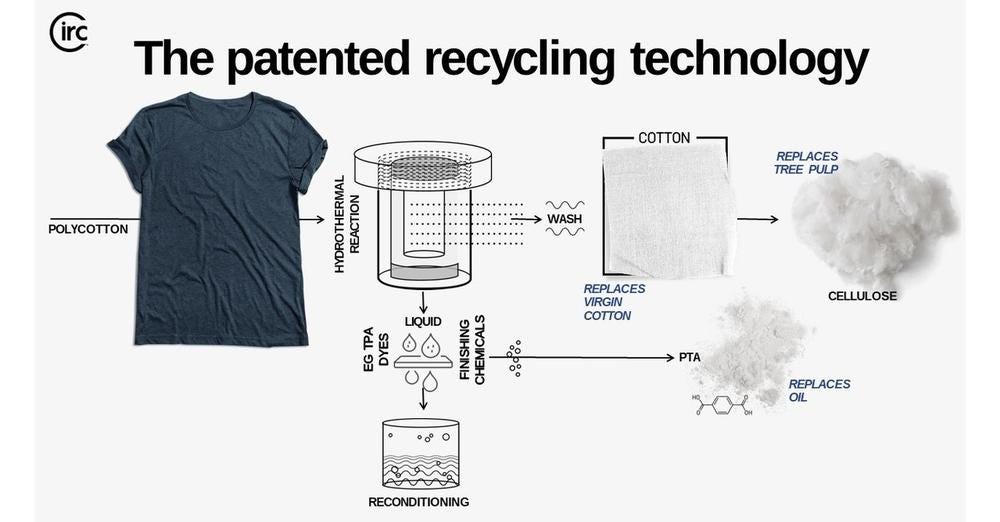

Circ helps industries meet consumer expectations for sustainability without compromises in quality, price, or convenience. It recycles discarded clothing to produce the basis of petroleum- and plant-based fabrics. Tyton’s virgin-equivalent, market-grade dissolving pulp, and petroleum monomers can be sold at the same cost as virgin materials to manufacturers who make fibers. Whether cotton, poly-cotton, polyester, nylon, or other fibers, it aims to cost-effectively recycle these materials using water as a solvent.

They’ve created a technology system that returns clothes to the raw materials from which they were made. Brand partners like Patagonia, Marubeni, and Fashion For Good are joining Circ in its goal of turning wasteful fashion lines into renewable fashion circles. By 2030, they expect to have recycled 10 billion garments, represent 10% of the global apparel market, and to have saved more than 100 million trees. As their ecology and economy grow evermore entwined, we can hope that the world already has all the clothing it needs to create all the clothing it will ever need.

1. Uncompromised quality: Circ understands the importance of maintaining exceptional product quality. Its cutting-edge recycling process converts discarded clothing into the foundation of petroleum- and plant-based fabrics. This enables manufacturers to create fibers that are on par with virgin materials, ensuring the highest standards of quality and performance.

2. Competitive pricing: In an industry where cost considerations are paramount, Circ offers a unique proposition. The virgin-equivalent, market-grade dissolving pulp and petroleum monomers produced by Circ can be sold to manufacturers at the same cost as virgin materials. By eliminating the premium associated with sustainable sourcing, Circ enables your company to maintain competitive pricing strategies while still embracing sustainability.

3. Convenience and versatility: Circ's technology supports the recycling of various textile materials, including cotton, poly-cotton, polyester, nylon, and more. With a focus on cost-effectiveness, Circ employs water as a solvent in the recycling process, ensuring convenience and ease of integration within existing manufacturing operations. This versatility allows your company to expand its sustainability initiatives across diverse product lines and target a wider range of consumer preferences.

4. Established expertise: Founded in 2011 and headquartered in Danville, Virginia, Circ boasts a strong foundation of knowledge and experience. The company has been at the forefront of sustainable textile recycling, continuously refining its processes and technologies to meet industry demands. By partnering with Circ, you gain access to a trusted partner with a proven track record in sustainability, reinforcing your own brand's commitment to responsible practices.

In an era where consumers increasingly prioritize sustainability, joining forces with Circ will position your company as an industry leader in environmental responsibility. By capitalizing on Circ's innovative technology, you can differentiate your products and services while meeting the ever-growing demand for eco-friendly solutions.

Circ announced last year a $30 million Series B funding round, led by Bill Gates-founded Breakthrough Energy Ventures, with additional investment from Inditex, Milliken Textiles, Temasek, and Lansdowne Partners.

Bonus track by Anthony

You can access the full nouveau monde playlist here on Spotify.

Thanks for reading Nouveau Monde! Subscribe for free to receive new posts and support our work.